Laser cutting and plasma cutting are two pivotal technologies in the fabrication industry, each with unique features that make them preferable for specific applications. This article delves into a comparative analysis of these two cutting technologies based on four critical parameters: cutting process and principle, material compatibility, precision and quality, and speed and cost.

Cutting Process and Principle

Laser cutting works by directing a high-power laser beam onto a specific point on the material. The intense heat generated by the laser causes the material to melt, burn, vaporise, or, in some cases, ignite. The trajectory of the laser beam is controlled using computer systems, which ensures the cuts are highly precise.

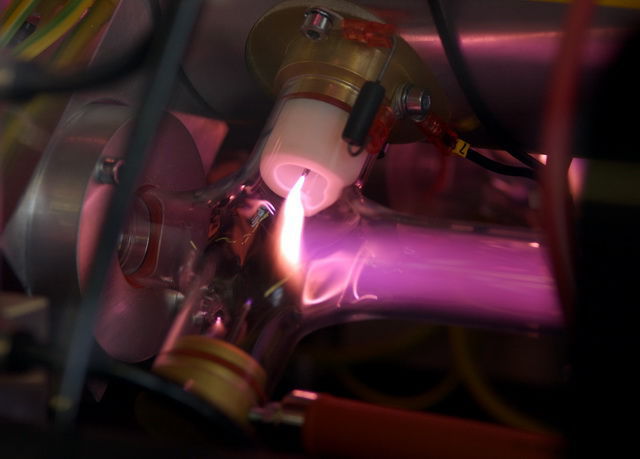

Plasma cutting, in contrast, utilises a jet of ionised gas, referred to as plasma, which conducts electricity from the torch of the cutter to the workpiece. The heat generated by the plasma melts the workpiece, and the resulting molten metal is blown away by the high-velocity plasma gas, thus creating a cut.

Material Compatibility

Laser cutting is compatible with a wide array of materials. It works well with metals such as steel, aluminium, and stainless steel, as well as non-metallic materials like wood, glass, and various plastics. While it can handle materials of varying thickness, its efficiency drops when dealing with particularly thick materials.

In contrast, plasma cutting is largely used for cutting metals, especially those that are conductive. These include stainless steel, aluminium, copper, and brass. It copes better with thicker materials compared to laser cutting, making it an excellent choice for heavy-duty industrial tasks.

Precision and Quality

Laser cutting stands out in terms of precision. It provides exceptionally high accuracy and yields a smooth, clean cut edge. This technology can manage intricate shapes and small holes with remarkable precision, making it an ideal choice for detailed work or applications necessitating high precision.

While plasma cutting does not match the precision of laser cutting, it delivers adequate cutting quality for many industrial applications. However, it may produce a heat-affected zone and some dross (residue) around the cut edge, which might require further processing.

Speed and Cost

Plasma cutting generally offers faster cutting speeds than laser cutting, especially when dealing with thicker materials. It is also less expensive in terms of equipment and operational costs, thereby providing a cost-effective solution for many businesses.

Laser cutting equipment, while often more expensive, can prove cost-effective for certain applications. The precision it offers reduces the need for post-cut finishing, and the ability to cut complex shapes can make it a more efficient choice for projects demanding high accuracy.

In conclusion, both laser cutting and plasma cutting have their unique strengths and are better suited to different applications. Choosing between the two depends on several factors, including the material type and thickness, the required precision level, and budgetary considerations. A thorough understanding of these differences is essential to make an informed decision that aligns with your specific cutting requirements.