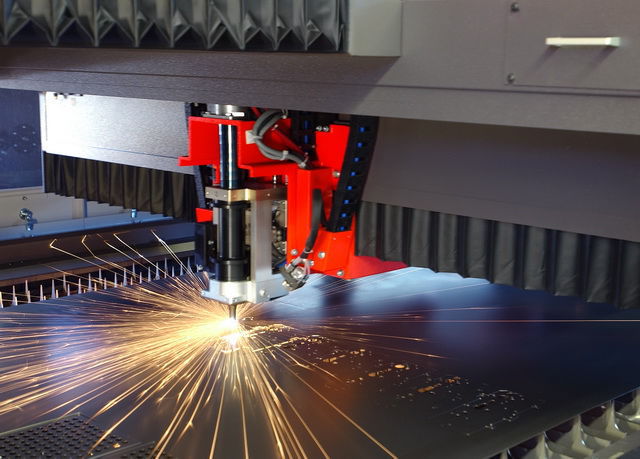

It’s a bird! It’s a plane! It’s a …brand new top of the market laser cutting machine…? Granted, it doesn’t quite have the same ring to it, but you can’t tell me you haven’t noticed more and more companies using laser cutting machines. No? Let me give you the 411.

First off, let’s just acknowledge the obvious. It’s a laser. You don’t even have to know what this machine looks like, or have used one yourself, to have some clue of what it does. Even if you’re using a tiny toy laser to play with your cat, you can easily list three facts about it off the top of your head: it’s precise, easy to control, and easy to create.

Replacing human with technology can always be a scary notion. But think about the benefits at hand here, both as an employer and an employee. Any health-related injuries (such as migraines, headaches, or neck/back strain from focusing on such detailed tasks) can be minimised.

Similarly, employers don’t have to worry about filing Worksafe documents, finding cover shifts, or dealing with cranky clients because the job is taking too long. Any good employer knows the first step to dealing with potential risk in the workplace: elimination. Physically remove the hazard from becoming a problem in the first place.

Unlike when you rely on human involvement, a laser cutting machine is efficient and precise. It is made for the specific purpose of designing intricate and minute details, all the way down to tiny leaves half the size of a fingernail. And I have small fingernails.

Do you think you can guarantee the same result using other tools? Can you recreate the design of, say, the lead lighting on Notre Dame’s rose windows with a handsaw or Stanley knife? More importantly, can you do this same design over and over without creating flaws or accidentally changing the design?

Any business worker knows the importance of consistency, regardless of their industry. Look at a patisserie or café. The chef is encouraged to be creative and attract customers through the taste and design of their product. But, each cake, slice, cupcake, whatever it is…it has to be the same. With a machine controlling this process at hand, you are guaranteed to get the same result. Every. Single. Time. No small changes, accidental cuts etc. One hundred per cent accuracy and consistency. The perfect combination!

Let’s also not forget that in addition to these two factors is the versatility of the machine. That is, it can cut through basically any material, including plastic, wood, and quite a few types of metals. Would you rather use five tools to cut one material... or one machine that can cut through five materials? Like I said, very efficient. When you consider the price you pay for using the machine, which can be quite reasonable might I add, it’s a pretty good deal.

You’re paying for fewer risks, fewer tools, fewer time constraints…win, win, win, hey? So really, if you look at it this way, the real question at hand should be ‘what are you waiting for’?